AQUATHERM ENERGY

Aquatherm in the specialized prefabrication factory, in its industrial complex in Attendorn Germany, carries out the manufacture of manifolds up to Ø630mm in diameter, as well as any other special prefabricated component required.

Having more than 45 years of experience in PPR, state-of-the-art special equipment as well as highly specialized staff, aquatherm offers a very high-precision pre-fabrication to ensure for customers:

• Reduced installation time.

• More precision due to detailed design.

• Possible to install in confined space.

• Not necessary to use very high cost manifold tools in the project and the correspondingly highly qualified personnel, thus preventing possible improvisations in the project.

• No delays due to lack of specific components. Decrease of dead-time.

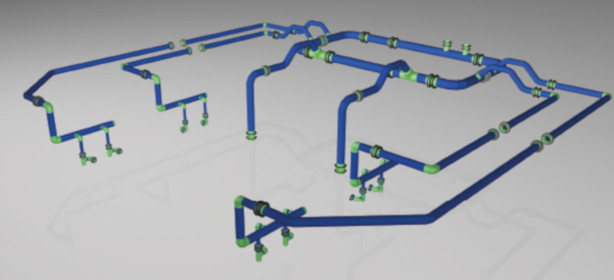

• Possible to prefabricate complex installations, entire engine rooms by delivering special prefabricated parts with flanged ends for assembling on site.

STEPS OF CONSTRUCTION

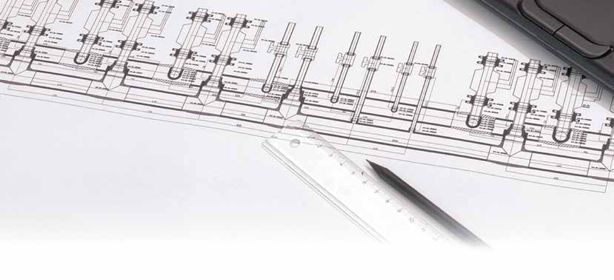

At first, customers send to aquatherm the designs of the pieces that they want to be pre-fabricated in CAD, 3D, or even simple sketches with the exact dimensions they want.

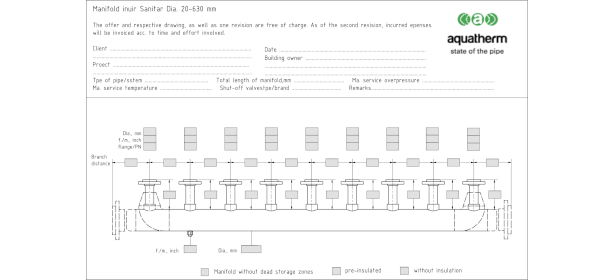

Alternatively, they can complement the special manifold inquiry forms provided by aquatherm.

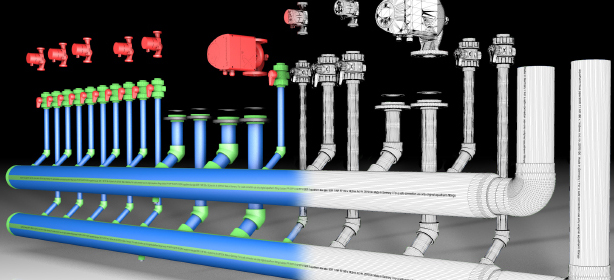

Then, the aquatherm design team sends you three dimensional drawings with detailed design of all the individual parts that constitute the special component, thus minimizing design errors and ensuring very high pre-fabrication accuracy.

The aquatherm industrial prefabricated components (manufactured in Germany) are certified according to ISO 9001, ISO 14001, ISO 50001 and delivered to customers after they pass a factory waterproofing test, while like all our products, are covered by a 10 year warranty, up to 20,000,000 euros from the international insurance company AXA.

Having more than 45 years of experience in PPR, state-of-the-art special equipment as well as highly specialized staff, aquatherm offers a very high-precision pre-fabrication to ensure for customers:

• Reduced installation time.

• More precision due to detailed design.

• Possible to install in confined space.

• Not necessary to use very high cost manifold tools in the project and the correspondingly highly qualified personnel, thus preventing possible improvisations in the project.

• No delays due to lack of specific components. Decrease of dead-time.

• Possible to prefabricate complex installations, entire engine rooms by delivering special prefabricated parts with flanged ends for assembling on site.

STEPS OF CONSTRUCTION

At first, customers send to aquatherm the designs of the pieces that they want to be pre-fabricated in CAD, 3D, or even simple sketches with the exact dimensions they want.

Alternatively, they can complement the special manifold inquiry forms provided by aquatherm.

Then, the aquatherm design team sends you three dimensional drawings with detailed design of all the individual parts that constitute the special component, thus minimizing design errors and ensuring very high pre-fabrication accuracy.

The aquatherm industrial prefabricated components (manufactured in Germany) are certified according to ISO 9001, ISO 14001, ISO 50001 and delivered to customers after they pass a factory waterproofing test, while like all our products, are covered by a 10 year warranty, up to 20,000,000 euros from the international insurance company AXA.